Ta-Tronic

Heads with automatic balancing for numerical control boring and facing, which are applied manually, automatically, and with palletized systems, on boring machines, machining centers, and special machinery.

General features.

TA-Tronic boring and facing heads can be manually or automatically applied on small boring machines, machining centers and special machines.

Connection with the machine tool spindle occurs through a cone for the rotation of the rotating head and a flange for fastening the fixed body on to the fixed part of the machine. For lighter tasks a simple anti-rotation pin may be used.

Two possibilities are available for the control unit of the TA-Tronic head:

– The first one involves a direct connection to the “U” axis of the NC in the machine tool which allows boring, inner facing, outer facing, back–facing, grooving, phonographic grooves, threading and taper boring, taper and variable boring, concave and convex corner rounding through interpolation with the other axis.

– The second with a simple and economical U-CONTROL positioner with a wireless REMOTE-CONTROL. The positioner can be connected to the M functions of the machine to receive start signals of the various operations programmed on the REMOTE-CONTROL. This solution allows boring machining, inner facing, outer facing, back-facing, inner and outer turning operations, grooves, phonographic grooves, threading, and taper boring. Spherical machining is not possible with machines equipped with the U-CONTROL WIRELESS KIT.

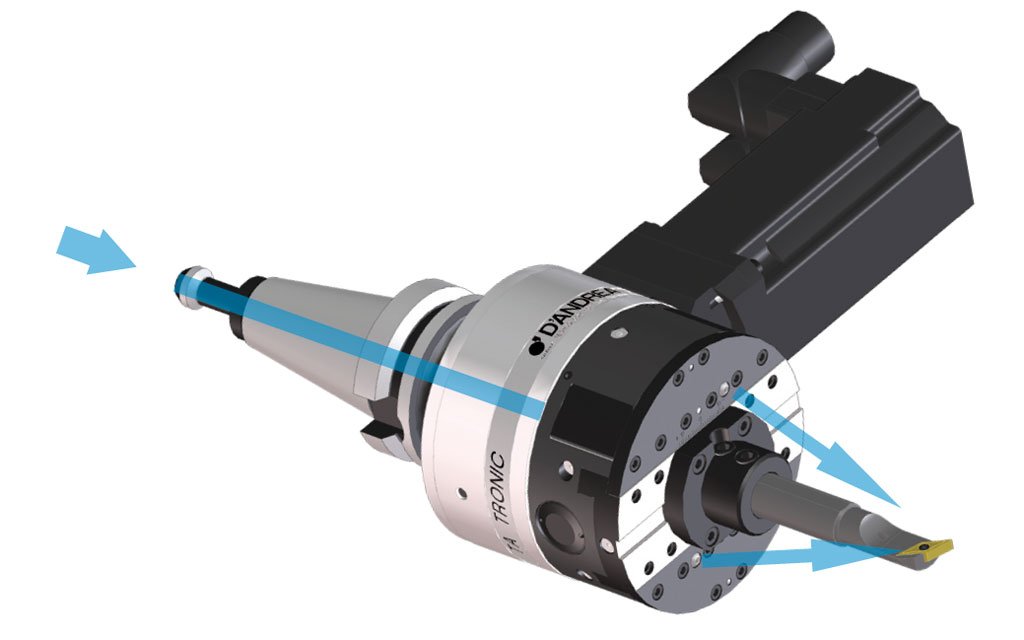

Coolant supply

Coolant exits from the two adjustable nozzles in the TA-TRONIC located next to the slide after crossing the taper and the rotating body of the head. This noteworthy advantage ensures longer duration of the insert, quicker cutting speed and achievement of good surface finishes.

The centralized supply of coolant does not harm the TA-TRONIC, its internal labyrinths are protected by O-rings. It is advisable to not exceed a pressure of 40 BAR.

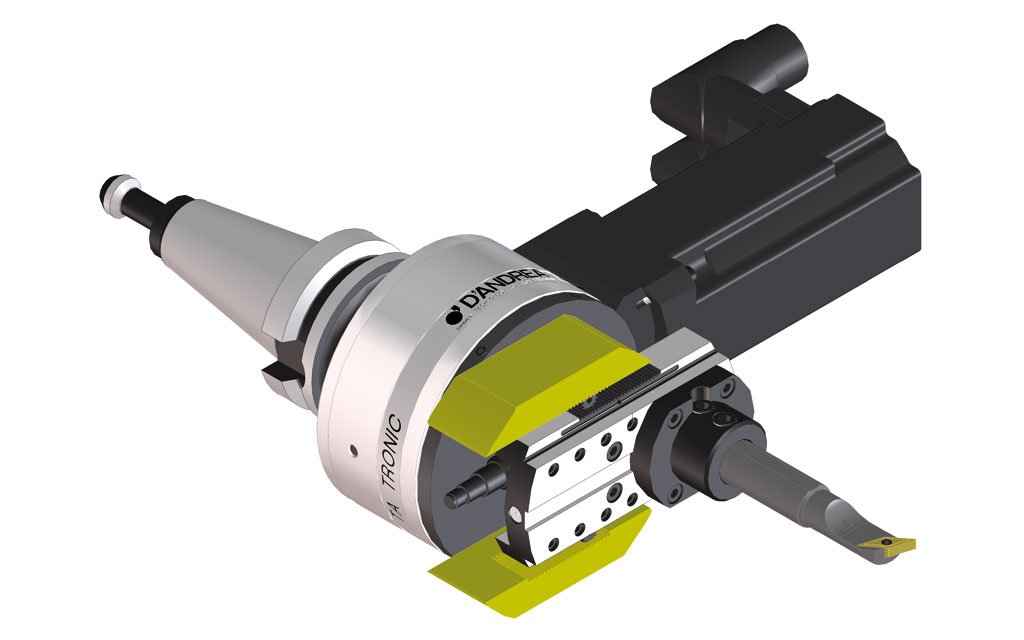

Balancing

TA-TRONIC heads are designed with two counter-weights for automatic balancing, which move opposite to the slide making it possible to machine at a higher number of rpm without noticeable oscillations.

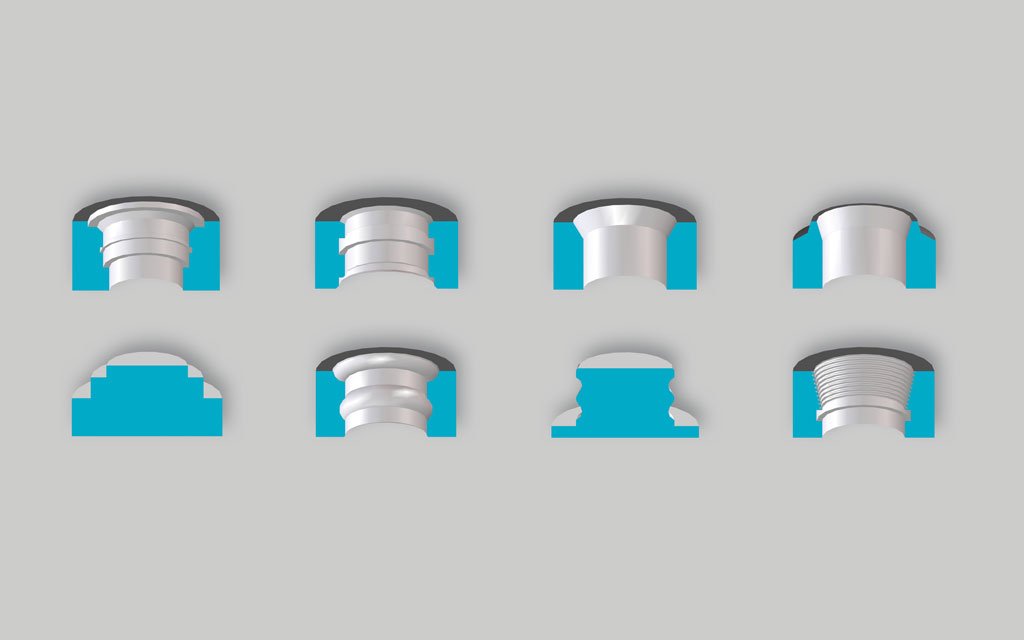

Tool applications

Standard tools can be mounted on D’ANDREA toolholders to perform simple and multiple machining of internal and external turning operations, tapered and variable boring, concave and convex corner rounding, grooves, cylindrical and conical threading, facing, phonographic grooves, etc.