Ceramics for high-speed machining

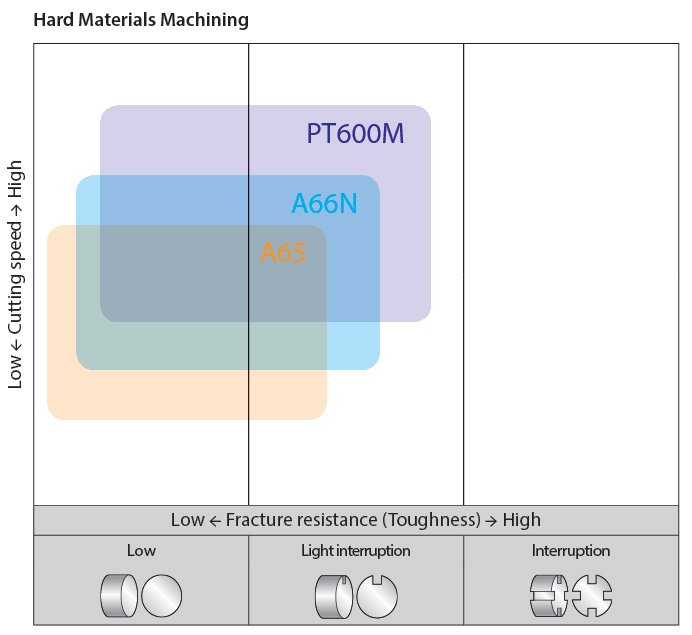

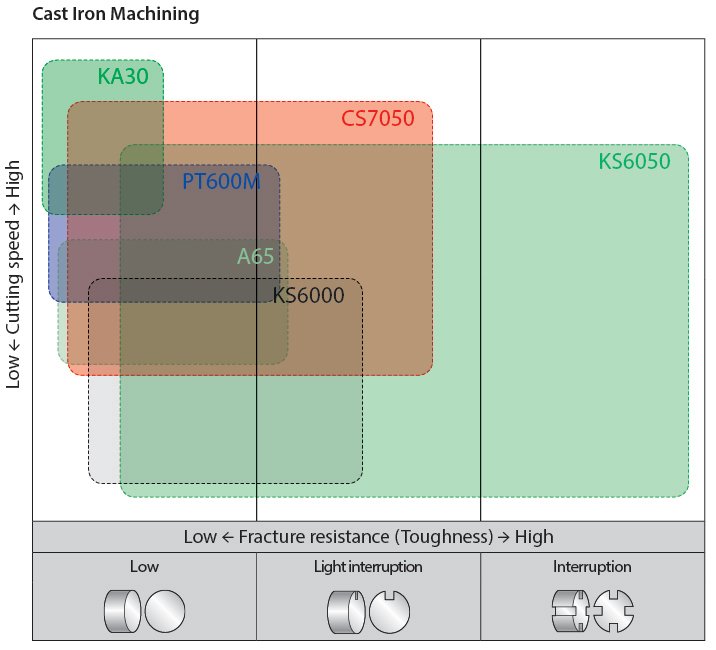

Kyocera ceramic inserts are capable of running at high speeds, thus reducing expensive machining time. Ceramic inserts are recommended for turning of carbon and alloy steels (38-64 Rc) or rough/finish turning of cast iron.

Kyocera’s ceramic inserts are designed to resist oxidation and maintain hardness at elevated temperatures.

Features of ceramic inserts

Superior heat resistance enables high-speed machining (aluminium oxide ceramic). Kyocera’s ceramic inserts ensure good surface quality due to low affinity to the workpiece material. Silicon nitride ceramic (KS6000) has improved thermal shock resistance allowing cast iron machining using coolants.