CA5 – process safety in your production

The market requires a robust production process. Kyocera helps you achieve that with a superior tool giving you optimum chip control, long tool life and stable machining.

The new CA5 is no exception, raising the bar further with a newly developed chipbreaker, new coating technology and much more.

Reliable processes

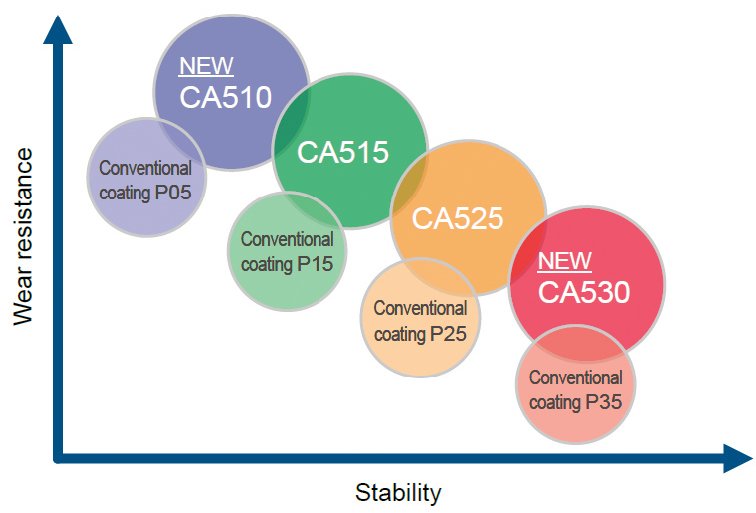

Newly developed CVD-coated carbide grades with further improved properties give optimum results and high process security.

• CA510: Turning with high cutting speed

• CA515: Continuous to light interrupted machining

• CA525: General use

• CA530: General to heavy interrupted machining

Increased productivity

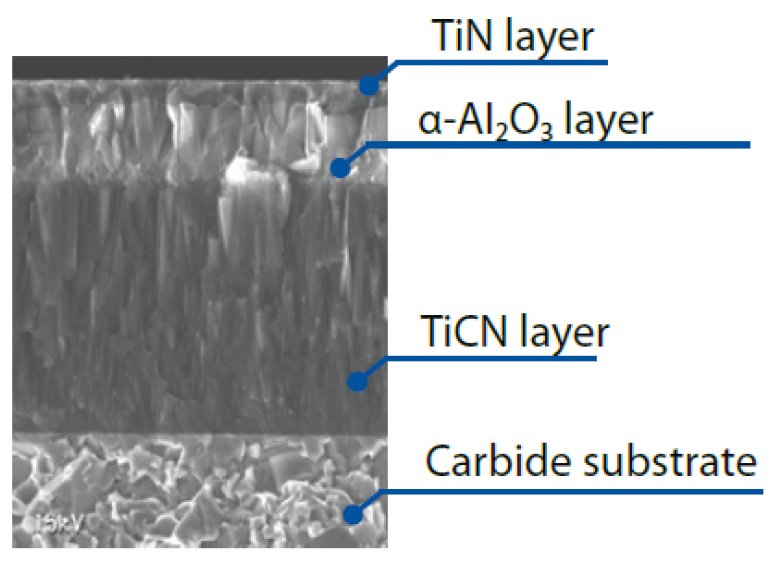

Newly developed carbide substrate with 10% improved hardness at high operating temperatures. That means the turning insert is more resistant to plastic deformation, tool life is improved and high-efficiency turning achieved.

Long tool life and stable machining

The new coating technology has a 40% improved adhesion to the new carbide substrate. That gives the turning insert a reduced and more controlled wear. An increased ratio of a-AI2O3 layer produces superior hardness and toughness, resulting in longer tool life.

The smooth and flat surface means less friction, preventing sudden breakage caused by material welding onto the cutting edge. It also means less heat development and reduced cutting forces. Moreover, the coating technology has been improved applying a special crystal control technology.

Less downtime

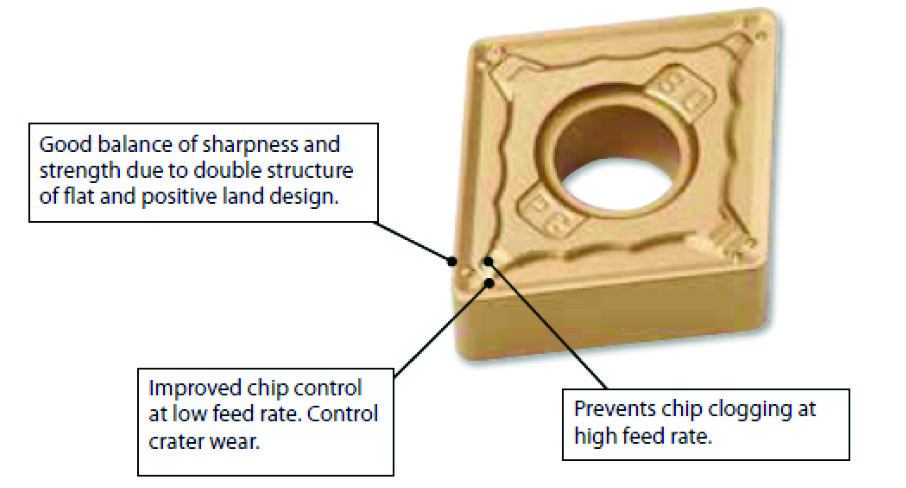

In order to achieve process security in production, Kyocera has always focused on optimum chip control with a wide range of chipbreakers for various applications.